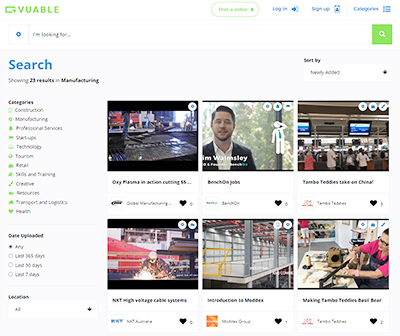

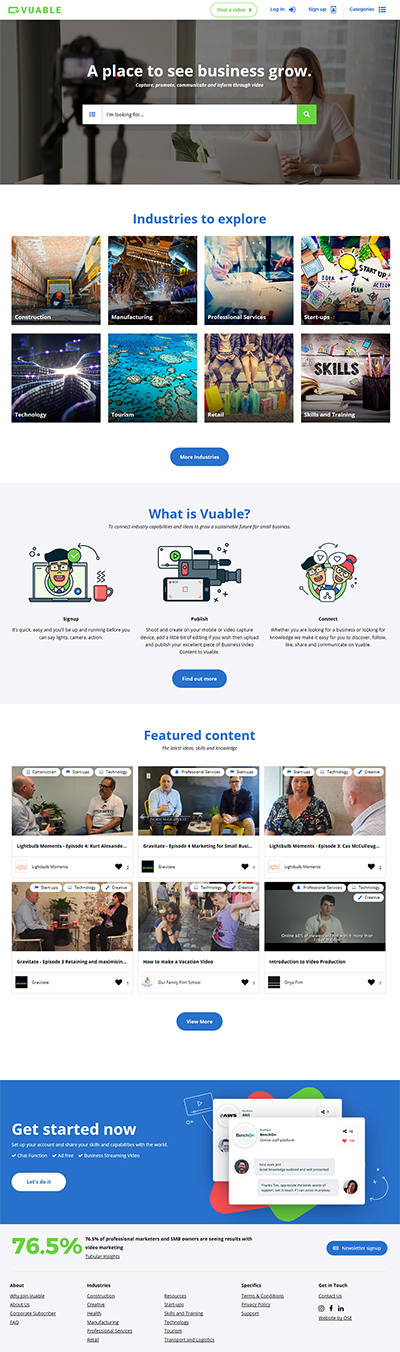

QMI’s new Vuable video social network helps industries innovate

THE NEW VIDEO social network launched by QMI Solutions aims to do a lot more than help drive industry innovation through moving pictures.

The Vuable team believes that fostering ideas, skills and experience will ensure a sustainable and prosperous future for Australia’s industries. The Vuable video platform will interlink small and large business, including innovators, researchers, start-ups and project owners.

Founded 25 years ago as the Queensland Manufacturing Institute – and now a national industry solutions catalyst and technology disseminator – QMI Solutions is well known for taking the lead in introducing new technologies to the manufacturing sector, successfully.

QMI Solutions managing director and CEO, Gary Christian – who pointed out that QMI successfully introduced the first industrial 3D printing system into Australia 20 years ago – said Vuable had been created in direct response to industry challenges in visibility, market access, collaboration and innovation.

Mr Christian also foresees Vuable having a significant role in connecting Australian researchers with industry and in helping companies market their innovations and products nationally and, eventually, internationally.

“Gary is right about that and it is the research into this area that we used to shape Vuable,” QMI Solutions’ Vuable co-creator Norm McGillivray said. “There is nothing like Vuable currently anywhere in the world.”

Mr McGillivray said the way the market has adopted video – through Facebook, Instagram and SnapChat stories – is an indication of how a well-planned and astutely organised video platform like Vuable could positively impact industry business growth.

“When QMI started to research and investigate a new platform, we looked around the globe to see if we could find anything like it, one that was solely tuned to industries and innovators,” Mr McGillivray said.

“We thought, ah! Obviously, YouTube and other social media platforms serve a diverse range of video content to the masses, but there was nothing just dedicated to industry and innovators.

“Vuable serves our stakeholders in the sectors in which QMI is already active – and that is suppliers into major projects, manufacturers and their intermediaries, projects in development and innovators,” he said.

“It is, however, not limited to these industries. We are talking with retail, tech and financial institutions about joining the network as well as major projects and our industry leaders including government departments and research organisations.”

INDUSTRIAL POWER OF VIDEO

Mr McGillivray said Cisco Systems had released a report earlier this year on the impact of internet-delivered video, estimating that by 2018 people would consume about 80 percent of their online information through video.

The growth of video information has been driven largely by the smartphone, Mr McGillivray said. Industry is rapidly coming to grips with its potential, with many already incorporating video into training and apps.

Mr McGillivray, who has been working with his team on Vuable for just over 12 months, said observations of the video trend is backed by QMI’s investment in the system.

“I see small businesses in general already using video in many ways, along with larger organisations including government departments” he said. “Members of Vuable may initially use it to say who they are, what they do and who they work with. Taking their capabilities from text into the visual space”

“Research organisations and government departments will use Vuable to show what assistance programs are available, and what research organisations are doing currently.”

He said QMI could also see Vuable impacting the project space, highlighting major projects and being used practically for infrastructure to supply information, for contractors, community engagement, “and social good”.

Mr McGillivray said Vuable would almost immediately enable existing QMI Solutions customers to elevate their ability to market – an ongoing challenge in the manufacturing sector.

Mr McGillivray said in the initial planning stages of Vuable, a concern had been the capability of industry to create quality video updates – but the smartphone had virtually eliminated that concern. He added there would be a requirement of ongoing education to get industry comfortable about creating and publishing content, with confidence coming from seeing peers using the platform too.

There is also a range of “fantastic video editing apps that are either free or low cost as well as desktop computer options” he said.

“The use of mobile phone is key … You can use mobile technology to get the best outcome, we are practising what we preach and have created our own videos on smartphones” Mr McGillivray said.

VUABLE FEATURES

QMI Solutions has developed the Vuable platform in just over eight months, utilising in-house developers to adapt open-source software.

A useful feature is Vuable’s search functionality, which utilises hashtags, while full instant messaging capabilities are incorporated.

“This removes the friction from the dreaded cold call, and adds the ability for subscribers to interact, business to business, and arrange anything from meeting informally over a cup of coffee to arranging a site meeting at a business’s premises, we think this is a pretty cool feature,” Mr McGillivray said.

“Suppliers and innovators can come on-board and enjoy a free trial period of 30 days and if they don’t like it that’s fine,” he said. “But if they wish to continue it is a month-by-month subscription that’s $25 and they can upload their video any time they want. It’s very flexible, they have total control to pause and resume their subscription at any time.”

QMI has always been an innovator in technology adoption and dissemination.

The Vuable platform grew out of QMI Solutions’ own re-assessment of where digital was taking industries and enacting its own digital transition strategy.

The first instance of this was the introduction of the CoreValue business evaluation system to Australia and New Zealand. This was followed recently by QMI’s introduction of its Online Procurement System (OPS) that serves procurement for industry through a fully automated procure-to-pay system.

“These products are already successfully in the marketplace – and Vuable is the third product that we are bringing to market,” Mr McGillivray said.

“Vuable is another first of its kind and in the form of a dedicated video platform for industry and innovation. We are very proud of that,” he said.

“The vision of QMI is that QMI helps make new possible … Vuable will help us to supercharge that vision.”

ends

How to resolve AdBlock issue?

How to resolve AdBlock issue?