Using maths to cut cattle transport costs

EXTRA >>

A NEW TOOL developed by the CSIRO is helping reduce the cost and time of transporting cattle in Australia – and this can account for up to 40 percent of the market price.

The new tool developed by CSIRO, the Transport Network Strategic Investment Tool (TRANSIT), identifies ways to reduce travel distance and time, saving fuel costs, cutting down on wear and tear and minimising stress for both truck drivers and cattle.

Cattle face some of the longest journeys of any Australian commodity, according to the CSIRO. In northern Australia, cattle travel an average of close to 1000km, and as much as 2500km to reach east coast abattoirs.

“In developing this tool we completed the most comprehensive mapping of the cattle supply chain in Australia,” lead researcher Dr Andrew Higgins said.

“We can now use TRANSIT to identify key investments, large and small, at critical points in the supply chain, along with policy changes that might allow for better planning.”

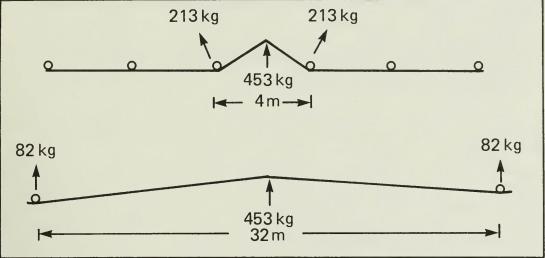

As well as establishing the most direct transport routes, TRANSIT can identify the best opportunities for infrastructure and policy development, including increased access for higher productivity vehicles on some roads, and improved links to rail.

By providing a holistic view of the direct and indirect transport costs across the entire road network, TRANSIT has informed many infrastructure and policy opportunities under consideration by governments, industry and community in northern Australia.

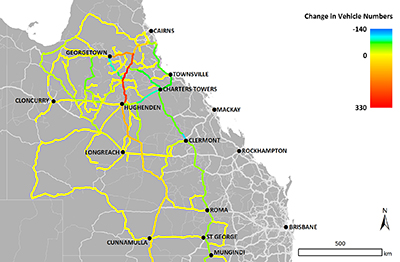

For example, TRANSIT has modelled the potential benefits of sealing the remaining 105km of the Hann Highway north of Hughenden in central Queensland.

The tool shows that this would reduce travel time on the Highway from five hours to three and a half hours, saving about 1160 hours for the estimated 1300 road trains currently using the road per year.

TRANSIT also identified that the number of road trains using the fully sealed Hann Highway would increase by 25 percent, as it would become an optimal travel route, removing heavy vehicles from the congested coastal highways.

These benefits translate to a modelled cost saving of $1.23 million per year, plus the additional savings from shorter return journeys for empty trucks and benefits to other road users.

“Other advantages from a more efficient supply chain are improved safety and welfare of the live animals and the truck drivers themselves taking these long journeys, reduced emissions, and a more sustainable industry at a time of growth,” Dr Higgins said.

For northern Australia, the TRANSIT project takes in data on 12,000 properties, finishing farms, sale yards, feedlots, export yards, rest stops, abattoirs and ports; and 15,000 road segments (ranked according to highway, major road or minor road, sealed or unsealed, among many other factors).

The team also consulted with transport operators such as Liz Schmidt, a director of Schmidt Livestock Transport in Townsville and past president of the Australian Livestock and Rural Transporters Association.

“The TRANSIT team’s consultation with industry has been especially valuable for the ‘mum and dad’ trucking operations with limited resources," Ms Schmidt said.

Dr Higgins said that beyond cattle, TRANSIT would now be applied to other agricultural transport, particularly degradable produce.

It is already being applied to the cattle industry Australia-wide – mapping the path of about 60,000 origin-to-destination movements representing 20 million cattle transported in Australia per year.

“It gives us a truckie’s-eye view of a supply chain, factoring in thousands of small decisions in planning routes,” Dr Higgins said.

“The beef industry has faced difficult times lately, but now there is a focus on northern Australia and all the northern states are planning for expansion.

"Our hope is that this tool can make every long journey as short as it can be, and help to expand sustainable industry.”

ends

How to resolve AdBlock issue?

How to resolve AdBlock issue?